Solving Client Challenges with Remote Engineering Services

December 26, 2023

One of the most satisfying parts of the job here at Unistrut Midwest is helping a customer solve their challenge with Unistrut channel. Over our many years of experience, we know there is nothing that our team can’t handle when we lean on our expertise and customer service.

We were recently contacted by an architecture firm on the West Coast who was completing some installations for a college. Although they were on the other side of the country, we knew we could guide them through the process from design to installation, and help them complete their project.

Challenge 1: Curved Unistrut Installation

The architecture firm first reached out to us to help solve the problem of installing curved aluminum ceiling panels for a utility screen. They had designed the panels to be dropped down from the existing ceiling to provide visual interest while masking cable, HVAC, and electrical.

A member of our sales team, Rory Moser, responded to the inquiry with the suggestion of using our standard galvanized steel strut instead of the requested aluminum since it has a negligible weight difference, costs significantly less, and has a wider range of available fittings. The customer asked for a recommendation on how to maintain a separation between the Unistrut system and aluminum panels, and Rory responded with a mockup of our suggested design.

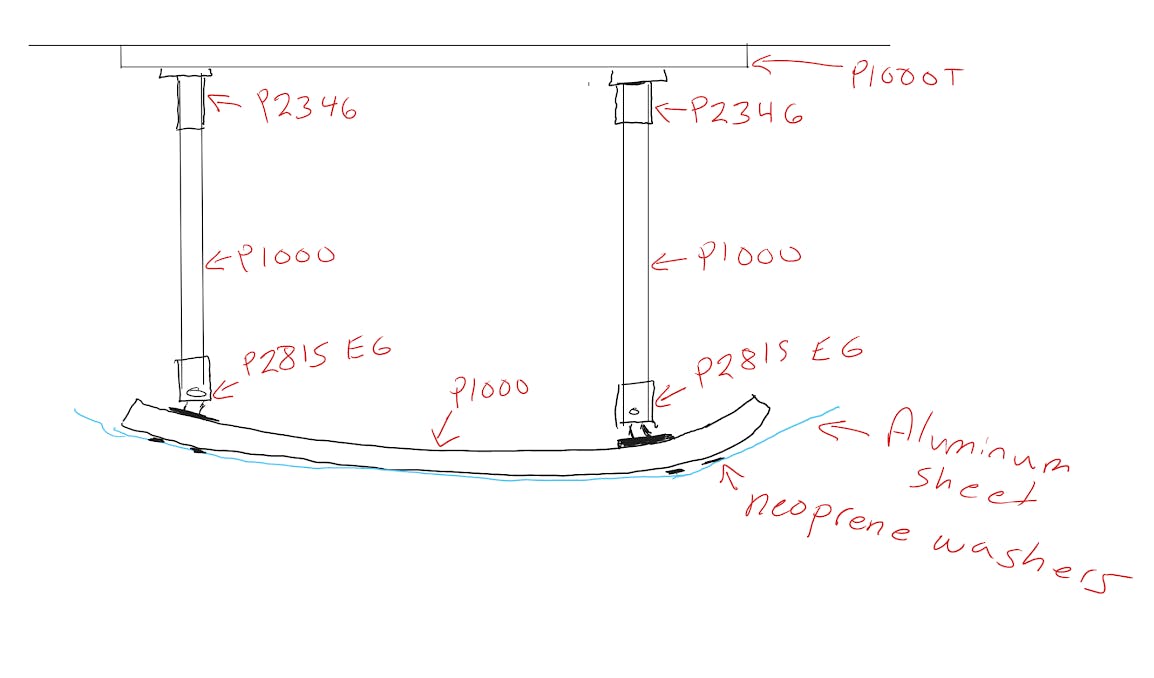

Using our slotted channel attached to the ceiling (P1000T), we would drop solid P1000 using our P2346 fitting. At the bottom of the drops, P2815 would connect to the curved Unistrut. From there, neoprene washers would connect the aluminum screens to the curved strut to avoid corrosion from dissimilar metals.

The customer was pleased with the design, and we sent them some samples so they could show their client the product.

With the design approved, our team sourced the required materials, sent out the Unistrut to be curved, and eventually sent all pieces to the architecture firm. The pieces were cut to size and labeled for easy installation by the architecture firm’s general contractor.

Despite not being on-site, our team was able to work with the customer to solve their problem, deliver the solution, and guide them through installation. The customer was so pleased with the service from our team that when another challenge arose for the same college, they came back to our team for help.

Challenge 2: Troubleshooting a Ceiling Grid

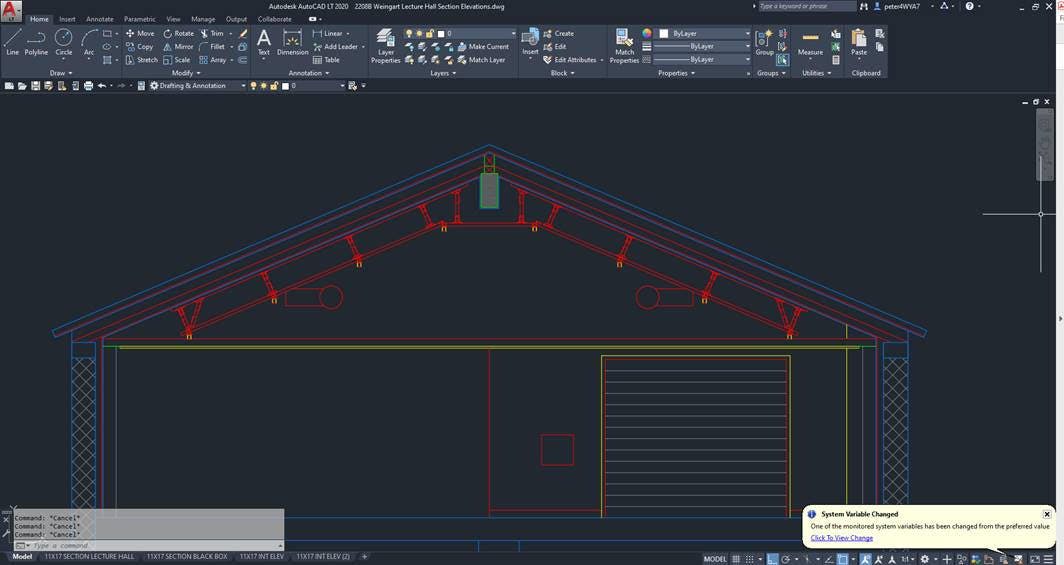

A few months after the initial ceiling utility screen project, our contact at the architecture firm reached out to Rory again with some questions. They were in construction on a second project for the college, using a Unistrut ceiling grid to create a suspended system that allows students to attach theatrical lighting and scenic backgrounds for their various projects.

While the system itself had already been designed, the architecture firm had some questions about connecting the system to the existing structure. She provided background specs on the design and desired solution:

- The Unistrut grid will hang approximately 12” below the existing ceiling and follow the slope of the gabled ceiling

- The ceiling is wood-framed

- Their goal was to connect the Unistrut grid to the ceiling with a wing-shaped fitting that will occur +-4’ o.c. in both directions

Her questions for Rory were:

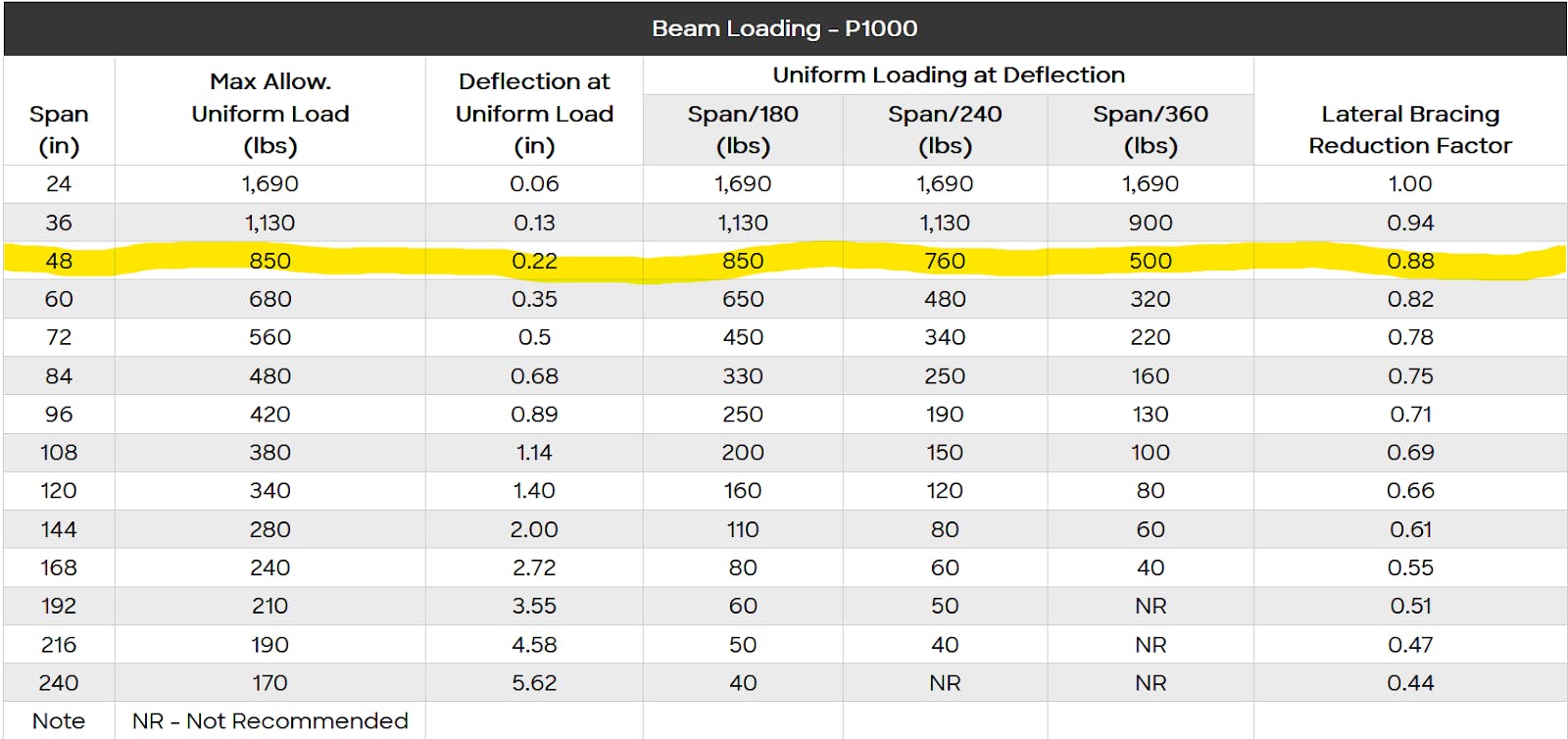

- Are there any limitations in regard to this being supported 4’-0” o.c.?

- What is the maximum point load, mid-span, that the channel can handle?

- If additional support is needed, would using a second P1000 attached directly at the ceiling help?

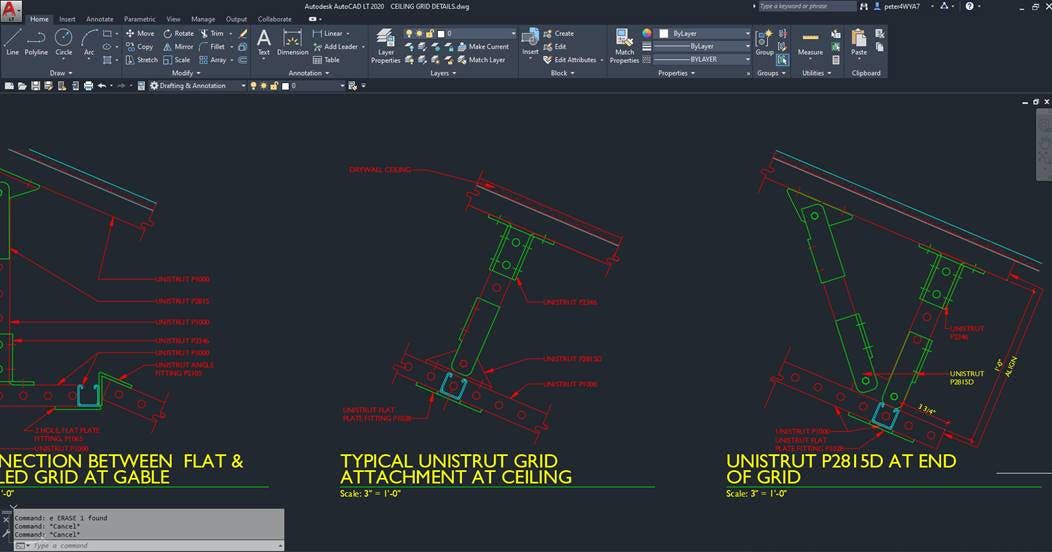

She also included more renderings of their intended installation setup.

With the provided information, Rory was able to confidently assure the customer that their solution was sound. He also provided beam loading data for P1000.

After that, the customer wanted a second opinion on the connection details their team had worked out for the other conditions of the grid. She wanted to be sure they had made the right choices and was interested in any recommendations or suggestions from our team.

Rory and our team reviewed the provided drawings to confirm that the designs were accurate for the intentions of the project and that they were following best practices. Rory did make a suggestion that would improve stability but confirmed that what the client had designed was appropriate and in fact, more cost-effective.

With renewed confidence provided by our team’s assessment, the customer was able to submit their plans to the city building department for approval.

Again, despite being thousands of miles away, Rory and our team were able to answer this customer’s questions and troubleshoot a few issues. Even though we weren’t involved in the initial design, we are always happy to provide a fresh set of eyes to a plan and make suggestions or improvements.

We are grateful that customers like this trust our expertise and we’re happy to be a resource to those needing help or reassurance. If you have a similar situation, feel free to reach out to our team for another opinion. We’d love to help make sure your solution is the best it can be.