Unistrut Finish Options

January 29, 2020

Unistrut Metal Framing is available in many finishes to meet various applications. Unistrut Midwest has experts available to help you determine the best finish for your project, but if you prefer to do your own research, we will cover the features and benefits of each finish to help you make the right selection.

Pre-Galvanized Unistrut

- Pre-Galvanized steel is zinc coated by a hot dip process and conforms to a G-90 thickness designation per ASTM A653. The thickness of the zinc coating is .75 MIL or .45oz/ sq ft. The Pre-Galvanized Unistrut Channel is the most common in the industry because its low cost and versatility in indoor and outdoor applications. The pre-galv strut is ubiquitous across all construction sites in the country. This is the default finish any contractor will use when none is specified.

- Common Applications for Pre-Galvanized Unistrut: Pipe Supports, Conduit Supports, Duct Supports in both indoor and outdoor applications.

Perma-Green Unistrut

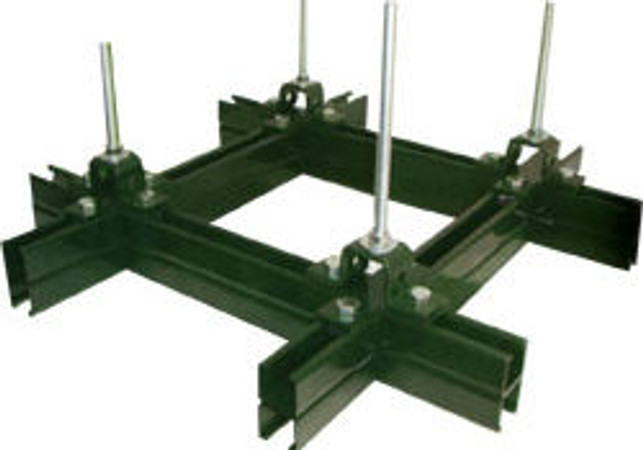

- Unistrut’s proprietary Perma-Green III Finish is a painted green finish that offers an exceptionally high performance coating for the strut channel and fittings. The Perma-Green Finish provides superior resistance to chalking, checking, and fading over traditional E.C. Coatings. The Perma-Green exceeds 400 hours on the Salt Spray offering decent corrosion protection. The Perma-Green Finish is unique to Unistrut which is why Unistrut Midwest will only use Perma-Green on our Medical Equipment Supports. The Perma-Green finish is primarily used in indoor applications such as hospitals, data centers, or light industrial.

- Common Applications for Perma-Green Unistrut: Unistrut Medical Equipment Supports, Unistrut Rack Systems, Unistrut Ceiling Grids

Plain Unistrut

- Unistrut with a “plain” finish designates that the channel retains the oiled surface applied to raw steel during the rolling process. No zinc coating, powder coating, or any other finish is added to the steel. This finish is preferred by OEM customers who will be either welding or powder coating the Unistrut channel in their fabrication process. This channel is recommended for any application that requires a custom powder coat finish. Plain Steel has no corrosion protection, so the channel will rust over time unless painted or galvanized after fabrication.

- Common Applications for Plain Unistrut: OEM Fabricated Supports, Custom Powder Coated Applications

Hot-Dipped Galvanized

- Hot Dipped Galvanized Unistrut is the original finish to be used in corrosive environments. Hot Dipped galvanizing requires the finished steel product to be immersed in a bath of molten zinc. The thickness of the zinc is three times the pre-galvanized finish (roughly 2.6 MIL). The added thickness of zinc coating provides additional corrosion protection. All standard Unistrut channels and fittings are available in hot-dipped galvanized finish. Until Unistrut Defender was released, this was the primary finish for outdoor and slightly corrosive applications.

Unistrut Defender

- Unistrut Defender is the newest finish offering by Unistrut. The Defender coating is a proprietary finish developed for Unistrut for outdoor and harsh corrosive environments. The Defender finish offers 3 times the corrosion protection of hot-dipped galvanized at a similar price point. Unistrut Defender is rated for a service life of over 30 years which is comparable to 304 Stainless Steel. Defender channel passed a 3,000 hour salt spray test. The Unistrut Defender offers unique self-healing properties that do not require touch up paint when cut or scratched. Unistrut Defender is still a new finish so only the most common channel, fittings, and hardware is available. Check with your Unistrut Midwest rep for recommendations on which components are available in Defender finish.

- Common Applications for Unistrut Defender: Wastewater Treatment plants, Coastal Applications, Refineries, or other corrosive environments

Stainless Steel Unistrut

- Unistrut channel is available in three grades of stainless steel, 304 Stainless (SS), 316 Stainless (ST), and 321 Stainless (XS). Stainless Steel Unistrut is a high quality, corrosion resistant material that is ideal for outdoor applications, waste water treatment facilities, and other corrosive environments. Stainless Steel offers 5 times the corrosion protection over the hot-dipped galvanized Unistrut. For pharmaceutical, food processing, and other clean room applications, Unistrut offers a stainless steel Food Grade Strut product line.

- Note: Most channel profiles are available in 304 and 316 Stainless. 321 Stainless is a custom, made to order item only available in the P1000 profile.

Custom Powder Coat Options

- Unistrut Midwest offers our Unistrut Channel in Black and White as standard color options. We can also custom paint our channel to match any RAL number. The custom painting adds cost and lead time but is available for our channel and fittings. Ask your sales rep today for custom paint options.

Black Unistrut Grid | Red Unistrut Grid |  White Unistrut Grid |

For more information on all Unistrut Finishes, check out our full site: Special Materials and Finishes